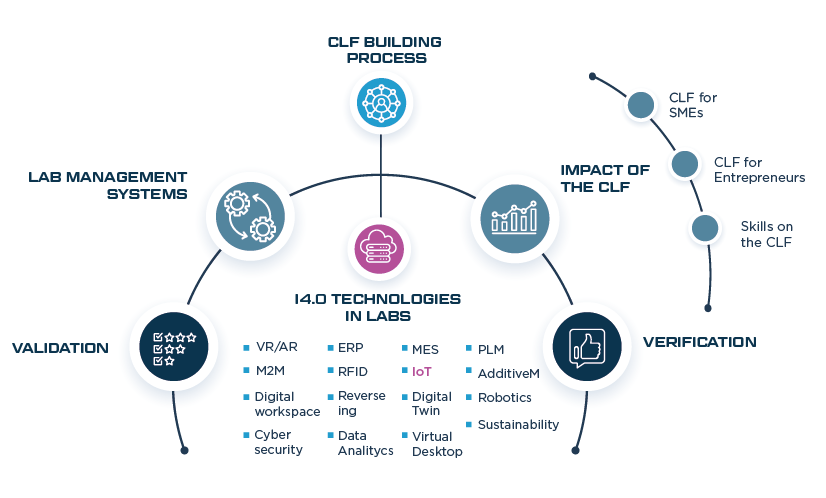

Following the piloting process of Advanced Manufacturing Labs for H/VET through the Collaborative Learning Factory (hereafter CLF), the EXAM4.0 partners we have piloted 16 technologies embedded in Industry 4.0.

The following image shows the overall structure of the piloting process.

Labs for Advanced Manufacturing-CLF

The present report is the one out of 16 I4.0 technology described within the “Industry 4.0 technologies in labs” section, specifically #1 Industrial Internet of Things (IIoT).

INDUSTRIAL INTERNET OF THINGS (IIoT)

The Industrial Internet of Things (IIoT) is the set of autonomous sensors, instruments and devices connected via the Internet to industrial applications. This network makes it possible to collect data, perform analysis and optimize production, increasing efficiency and reducing the costs of the manufacturing and service provision process. Industrial applications are complete technological ecosystems that connect devices and devices with the people who manage the processes in assembly lines, logistics or large-scale distribution (Iberdrola, 2021).

Today’s IIoT applications are mostly concentrated in manufacturing, transportation, and energy. In the immediate future, the adoption of the IIoT is expected to translate into the implementation of more industrial robots, such as cobots, warehouse and freight control systems, and predictive maintenance systems.

Figure 1: Idea of IIoT conexion in the industry. Source: https://www.iberdrola.com/innovacion/que-es-iiot

The difference between the Internet of Things (IoT) and its industrial version (IIoT) is that while IoT focuses on services for consumers, IIoT focuses on increasing security and efficiency in production centers.

Not all systems can be classified as IIoT. In general, it requires that they be networked systems that generate data for analysis and produce specific actions. The operation of IIoT systems is based on a layered structure:

-

Devices. The visible part of the system are the devices: sensors, GPS locators, machines, among others.

-

Network. Above it is the connectivity layer, that is, the network that is established between these devices and the servers through cloud computing or edge computing.

-

Services. They are the computer applications that analyse and process the collected data to offer a specific service.

-

Content. It is the interface with the human operator, which can be a computer, a tablet or even devices such as virtual reality glasses or augmented reality.

Among the applications that we can find in the IIoT are:

-

Autonomous vehicles: The transport of components to the plant or to the warehou- se, can be carried out by autonomous vehicles that are capable of moving from one side of the factory to the other detecting obstacles.

-

Machine performance optimization: An idle machine represents a loss of revenue. Thanks to sensors and data processing, it is possible to optimize machine uptime within a manufacturing plant. They can also detect times of use or errors for predictive and preventive maintenance.

-

Reduction of human errors: Human operators will continue to be essential in many tasks, but the tools they use will be connected to the system, to save time and avoid errors.

-

Improved logistics and distribution: The stored products incorporate sensors that provide real-time data on their location and even on their temperature or environmen- tal conditions.

-

Decrease in the number of accidents: Wearables, such as glasses, bracelets or gloves, allow data collection from the operator who wears them – from their location or proximity to the machines to their pulse, temperature or tension – and thus reduce the possibility of accidents.

IIoT IN HVET/VET LABS

In this section, we address how IoT technology can be incorporated into the laboratories of VET / HVET centres with the aim of acquiring data from CLF processes. With this goal, we have been working in Tknika’s I4.0 Factory Lab using SMC´s SIF-400 Learning Factory described in WP4, section D4.2, as a test bed to develop fully interoperable equipment for data acquisition and analysis.

Figure 2: Tknika’s I4.0 Factory Lab using SMC´s SIF-400 Learning Factory. Source: Tknika

SIFMES-400 allows the user to control and manage the SIF-400 system by storing and monitoring all process data. In the connected company, customers, manufacturers and suppliers are communicated and connected thanks to some of the functionalities of this software (SMCtraining, 2021).

It is structured in four blocks:

-

Management: production orders, planner, launcher, inventory, logistics, customers, maintenance, database and data analysis…

-

Movements: physical layout, logical layout, system reset and traceability of move- ments…

-

Visualisation: system status and alarms: maintenance, energy, analysis and statisti- cal process control…

-

Administration: Database, role and disturbance management (Instructor)…

This software represents a major step forward in digitalization and smart manufacturing due to the fundamental role played by this technology in the new industrial reality.

On the other hand, we have chosen to use technologies and apps that allow collaborative work, opting for those that have a strong developer community.

Figure 3: Teacher working on IIoT on Tknika’s lab. Source: Tknika

With these techonologies an IIoT gateway (Hardware & Software) has been developed allowing us to communicate with any industrial controller that speaks OPC UA, Modbus or S7 protocol. The gateway, called IoM2040, has been developed based on a Raspberry Pi 4, and a software package, called IoMBian (Raspbian Lite, Node RED, Mosquitto, MQTT client, Monit, Samba, etc). Everything has been designed to be easy to implement.

More information about these projects can be found in the following links:

- IoMBian: https://github.com/Tknika/iombian

- IoM2040: https://github.com/Tknika/iom2040

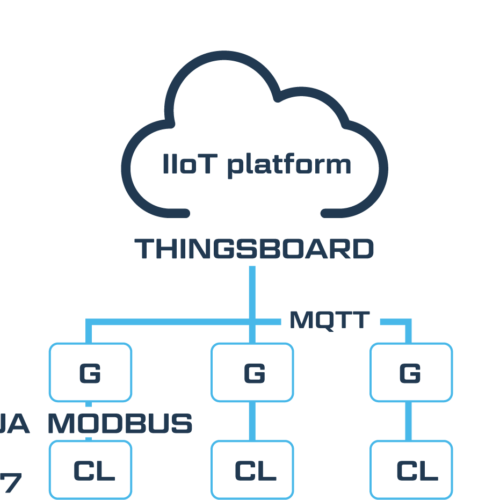

Figure 4: IIoT technologies in Tknikas’s lab. Source: Tknika

In the data analysis part, an IoT platform has been deployed in the cloud to provide service to the different CLFs. For that purpose Thingsboard has been chosen (Thingsboard, 2021). ThingsBoard is an open-source IoT platform for data collection, processing, visualization, and device management. It enables device connectivity via industry standard IoT protocols – MQTT, CoAP and HTTP and supports both cloud and on-premises deployments.

In this way the architecture of the IIoT system would look like this:

Figure 5: IIoT system architecture. Source: Tknika

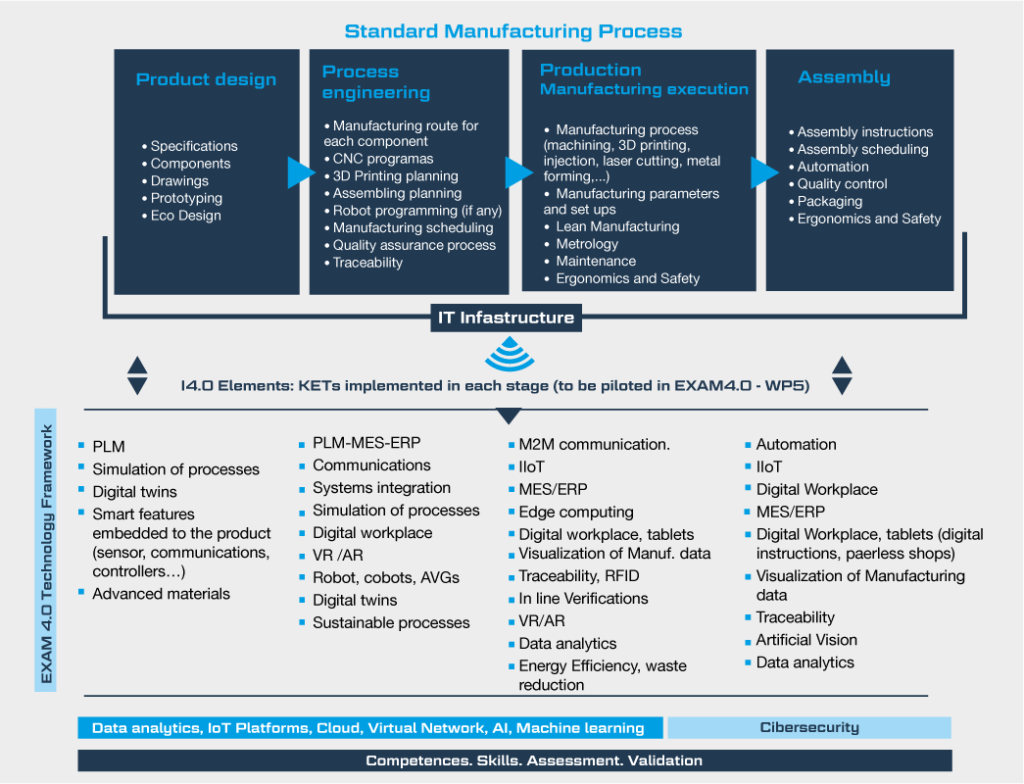

The CLF that is going to be launched has divided its production process into 4 stages (product design, process engineering, production and assembly) as can be seen in the following image. Within these stages, robotics is going to help in the process engineering, production and assembly stages.

Figure 6: Exam 4.o manufacturing process. Source: Author’s creation

The projects and services mentioned above will be used to connect machines in labs and collect data that will allow us to introduce process improvement iterations and share information between partners. This requires forming a new profile that is capable of managing both the installation and the development of the data collection and analysis ecosystem.

Based on our experience in this field, we will design a teacher training course focused on VET teachers with the aim of equipping them with technology to implement in the labs, but also allowing them to introduce this new knowledge as soon as possible in the classroom. In the pilot course, all the tools mentioned above will be taught to analyze the path traveled by the data from the production process (OT) to the cloud (IT).

There are huge benefits of adopting a fully connected IIoT manufacturing operation in the Labs. Some of these advantages are:

- Increase efficiency

- Reduce errors

- Improve security

- Reduce costs

- Share information

The greatest benefit of IIoT is that it provides the ability to automate and therefore optimize the operational efficiency of CLFs. Robotics and automated machinery can work more efficiently and precisely, increasing productivity.

Additionally, physical machinery can be connected to software through sensors that constantly monitor performance. This allows teachers and students to have a better understanding of the operational performance of the process.

Other advantages are:

- Data-driven decision making for all manufacturing functions.

- Performance monitoring from anywhere.

Among the competences that students will obtain working with IIoT platforms are:

- Obtain information to perform associated operations with the installation and commissioning of IoT systems.

- Configure the elements of the IoT system.

- Verify the operation of the IoT infrastructure, conducting functional tests on connected devices and systems, on site or remotely.

- Adapt to new work situations caused by technological and organizational changes in production processes.

- Identify the range of options for the way things can communicate.

- Select the most appropriate standards for building successful communications.

- Build addressing architectures that can scale to the required sizes.

- Analyse and record the interactions.

- Visualise the results of interactions.

- Deliver the security that modern services demand.

- Build new service networks that can support the future IIoT.

COLLABORATION OPPORTUNITIES OPENED BY IIoT

The IIoT platform will allow the creation of a community of connected CLF-s. For that purpose we have decided to use ThingsBoard and we have purchased the professional edition license. ThingsBoard is an open-source IoT platform that enables rapid development, management, and scaling of IoT projects.

With ThingsBoard, we will be able to provide this service to more CLF-s in the future being a service that can be offered to new partners from the EXAM4.0 platform. In the platform we will be able to:

- Provide devices, assets and customers, and define relations between them.

- Collect and visualize data from devices and assets.

- Analyze incoming telemetry and trigger alarms with complex event processing.

- Control devices using remote procedure calls (RPC).

- Build work-flows based on a device life-cycle event, REST API event, RPC request, etc.

- Design dynamic and responsive dashboards and present device or asset telemetry and insights to the customers.

- Enable use-case specific features using customizable rule chains.

- Push device data to other systems.