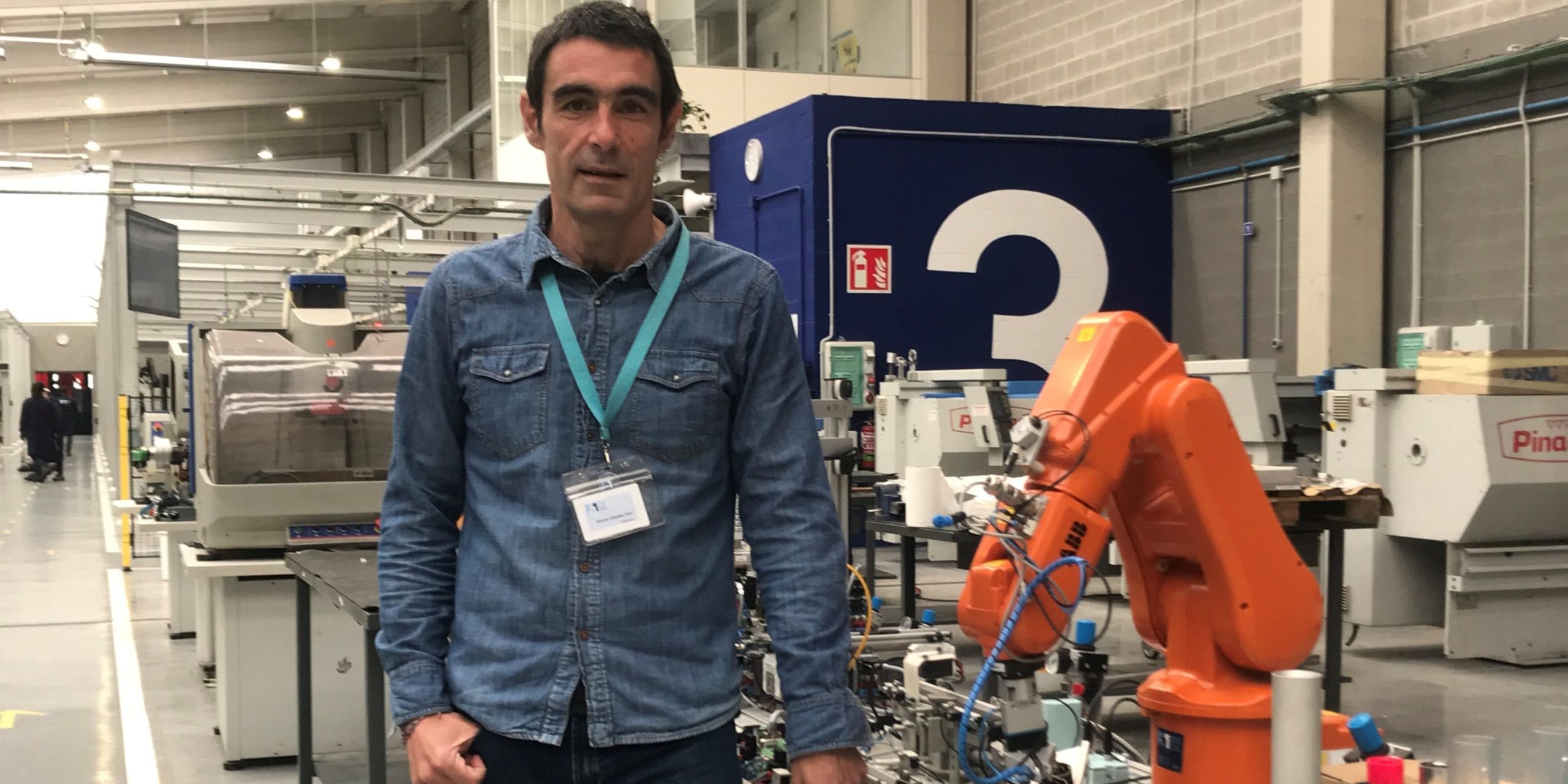

Unai Ziarsolo is a Senior Project Manager at CIFP Miguel Altuna. He has promoted the implementation of the advanced manufacturing lab at Miguel Altuna with a holistic view of the impact of the digital transition in VET centres, framed in the smart VET centres’ implementation strategy. Unai Ziarsolo is involved in many national and international projects mostly focused on advanced manufacturing (AM) from a VET perspective.

What are the main achievements that you can identify so far within EXAM 4.0?

After a conceptualization of the necessary adaptations for VET centres in terms of technologies, workshops, curricula, spaces and methodologies that the Industry 4.0 (I4.0) is requiring, we have created a Collaborative Learning Factory (CLF) for AM to pilot the most important findings. As a consortium, we are putting into practice the collaboration opportunities that Industry 4.0 is offering. We are also working on the structure and services provision for the platform for Advance Manufacturing. On the one hand, we intend this platform to become the meeting point for European Centres of Vocational Excellence (CoVEs) related to AM and, on the other, the reference for other stakeholders. This platform aims to boost regional innovation ecosystems. Nevertheless, EXAM4.0 is an open process, so we are facing a long-term journey. Once we demonstrate the virtues of CLFs for AM education, we expect that other CoVEs will join the initiative, and that the services included in the platform can be expanded, together with other stakeholders from regional ecosystems.

What activities did you carry out within the EXAM 4.0 project?

We are leading the work package where we put into practice the findings and conceptualizations from previous activities: the piloting of the AM labs. In order to combine the learning of new technical and transversal competences and the collaboration between partners, we have set up the EXAM4.0 Collaborative Learning Factory (EXAM 4.0 CLF), where we are introducing different Key Enabling Technologies (KETs) in manufacturing processes. The idea is to make the most of the options for collaboration and data exchange that I4.0 is offering. During the piloting phase, we are designing and manufacturing several mobile robots in four countries using a significant amount of I4.0 enabling technologies, emphasizing data exchange, co‑design and co-production.

What does “excellence” mean to you?

Excellence could be defined as meeting customer demands with quality, efficiency, rigour and deadlines, moving from working hard to working smart. However, to this definition we must add that excellence is achieved in organisations that are human-centred, inclusive, sustainable, supportive, integrated in regional ecosystems and that work for the well-being of the community to which they belong.

How is EXAM 4.0 achieving excellence?

The EXAM 4.0 consortium is developing a set of results that will support VET centres in our work towards excellence, both in operative and value-centred terms. We put special attention on the impact that I4.0 can have on people and how to face that form VET education: excellence is achieved by people.

Why is advanced manufacturing 4.0 (AM 4.0) a strategic sector to further develop VET?

AM is bringing about substantial changes in companies. Digital transformation is rethinking current business models and requires a transition to new organizational ones. One of the keys to this revolution is the adaptation of people to the new models. Many jobs are changing and so are the skills required. The role of VET in this context is decisive. We are challenged to train people with the new skills required as well as to reskill and upskill the labour force. In recent years, it has also become clear that, in order to respond to these challenges, VET institutions also have to digitally transform themselves and rethink their operating models, their learning methodologies and, in short, their organisation. Another lesson we are embracing is the need to cooperate with other stakeholders. We believe that, by working together and creating regional skills ecosystems, we will be able to face the digital transformation not as independent organisations but as interconnected regional actors and as a society.

What is the added value for your organisation to take part in a joint European initiative such as EXAM 4.0?

Excellence platforms are a learning community where each of us learn from each other with a common goal. It is an opportunity to learn, to cooperate, to share and to work on new challenges.

How are you implementing the preliminary results of the project within your school?

We are implementing new I4.0 features identified in EXAM 4.0 in our labs. In addition, the implementation of the CLF also requires students to participate in some of the activities, which is one of EXAM 4.0’s objectives. Many of EXAM 4.0’s conclusions and findings have been of great help in our current work on the development of new training and specialization programmes in smart manufacturing.