A learning factory (LF) is a learning environment where processes and technologies are based on a real industrial site which allows a direct approach to the product creation process. Learning factories are based on a didactical concept emphasizing experimental and problem-based learning. The continuous improvement philosophy is facilitated by own actions and interactive involvement of the participants. (Laperrière & Reinhart, 2015: CIRP Encyclopaedia of Production Engineering)

In the EXAM 4.0 Collaborative Learning Factory (CLF), a product is designed, produced and assembled in different locations, following the LFs principles — i.e., in learning environments where processes and technologies are based on a real industrial site. The co-creation process is based on continuous data and information exchange, with a fully collaborative approach. All this has a clear objective: to launch joint initiatives among Centres of Vocational Excellence (CoVEs) in the Advanced Manufacturing (AM) sector in order to share knowledge and experiences.

To reach this solution, the EXAM 4.0 partnership has identified the requirements that AM 4.0 labs require to implement 4.0 technologies. In the first stage, a state of art analysis was done, identifying the current status and future trends concerning technology, competencies and demands.

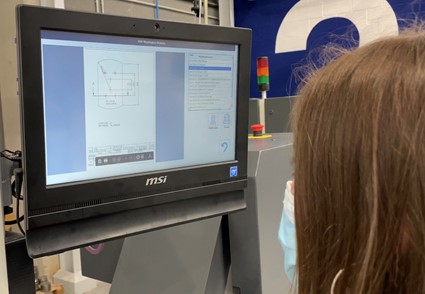

In a second stage, AM labs have been designed and modelled taking into account the 4.0 technologies analysed before. This design and modelling have been done defining their main features in terms of infrastructure, ICT applications, tools, skills needed and learning methodology.

Currently, the project it is in the stage of validation through pilot actions at VET centres. For this validation, it has been decided to pilot Industry 4.0 Labs at partners’ centres to verify the relationship and interaction among the different elements contained in the design. Active methodologies prone to be used in such labs will be identified and included.

Currently, the project it is in the stage of validation through pilot actions at VET centres. For this validation, it has been decided to pilot Industry 4.0 Labs at partners’ centres to verify the relationship and interaction among the different elements contained in the design. Active methodologies prone to be used in such labs will be identified and included.

The EXAM 4.0 CLF focuses on:

- the students

- the existing labs at each partner organisation

- the Industry 4.0 focus and future training plans at each institution

In order to create the CLF, it was essential to have a product and create a process for. The idea has been to create a mass-customization of a simple robot. This product will enable the creation of a process and facilitate the interactions between the different labs. At this moment, the different parts of the robot have been produced in different labs and have been sent to the German lab in where it will be assembled.